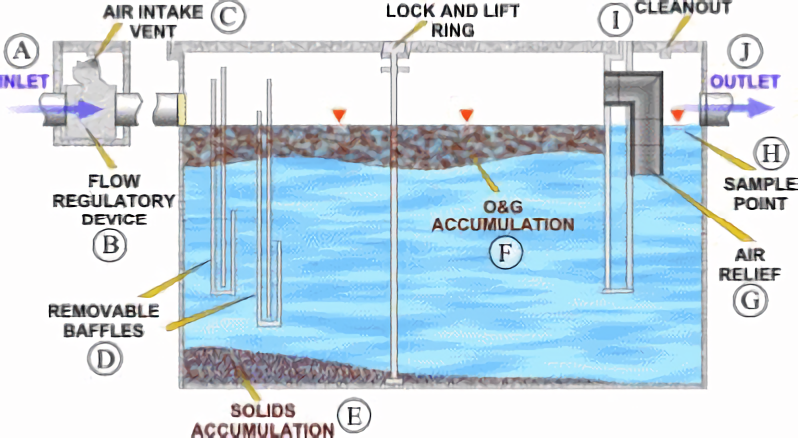

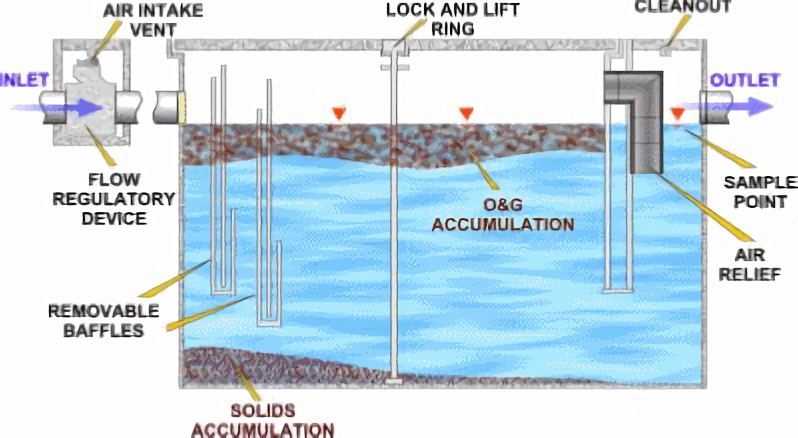

The Grease Trap - How it Works

- A. Flow from kitchen fixtures and or floor drains enters the grease trap.

- B. An approved flow control or restricting device must be installed to restrict the flow to the grease trap to the rated capacity of the trap.

- C. An air intake valve allows air into the open space of the grease trap to prevent siphonage and back-pressure.

- D. The baffles help to retain grease toward the upstream end of the grease trap since grease floats and will generally not go under the baffle. This helps to prevent grease from leaving the grease trap and moving further downstream where it can cause blockage problems.

- E. Solids in the wastewater that do not float will be deposited on the bottom of the grease trap and will need to be removed during routine grease trap cleaning.

- F. Oil and grease floats on the water surface and accumulates behind the baffles. The oil and grease will be removed during routine grease trap cleaning.

- G. Air relief is provided to maintain proper air circulation within the grease trap.

- H. Some grease traps have a sample point at the outlet end of the trap to sample the quality of the grease trap effluent.

- I. A cleanout is provided at the outlet or just downstream of the outlet to provide access into the pipe to remove any blockages.

- J. The water exits the grease trap through the outlet pipe and continues on to the grease interceptor or to the sanitary sewer system.

Grease Trap Maintenance

Grease trap maintenance is generally performed by employees of the establishment. Grease interceptor (GI) maintenance, which is usually performed by permitted haulers or recyclers, consists of removing the entire volume (liquids and solids) from the GI and properly disposing of the material in accordance with all Federal, State, and/or local laws. When performed properly and at the appropriate frequency, grease interceptor and trap maintenance can greatly reduce the discharge of fats, oil, and grease (FOG) into the wastewater collection system.

The required maintenance frequency for grease interceptors and traps depends greatly on the amount of FOG a facility generates as well as any best management practices that the establishment implements to reduce the FOG discharged into its sanitary sewer system. It is important to note that grease traps must not include any sanitary sewer connections from bathroom sinks, toilets or urinals. The exit line from the grease trap will connect into the sanitary sewer line. In many cases, establishments that implement best practices will realize financial benefit through a reduction in the frequency of required grease interceptor and trap maintenance.

In all cases, grease traps are to be considered as confined spaces and must not be entered.

Proper grease trap maintenance is required to insure that overall sewer system performance is not compromised. Failure to maintain systems often creates a blockage to the sewer disposal system! Additionally, it is a requirement of the Pulaski County Code of Ordinances. An excerpt is provided immediately below.

Sec. 42-61. General Sewer Use Requirements.

(a) Prohibited discharge standards. No user shall introduce or cause to be introduced into the authorities' collection systems any pollutant or wastewater which causes pass through or interference with the operation or performance of the regional systems. These general prohibitions apply to all users of the system whether or not they are subject to categorical pretreatment standards or any other federal, state or local pretreatment standards or requirement. Furthermore, no user may contribute the following substances to the system:

(17) Any discharge of fats, oils, or greases of animal or vegetable origin in sufficient quantity that may cause or contribute to the cause of restricting system flow to cause interference to the regional system.

(d) Pollutant limits. In addition to the general prohibited conditions set forth in subsections (a) through (c) of this section, specific limitations are established for certain compatible and toxic pollutants and other pollutants (see subsection (d)(1) and (2) of this section). Wastewater discharges having a daily average concentration greater than or instantaneous maximum concentrations five times greater than the below stated values (standards) will be controlled by a permit. Allocated limits above the standard may be approved by the authorities' director for compatible pollutants within the allowable mass proportion to average five-year annual flow allocated to the county by the authority. Allocated limits above the standard may be approved by the director for toxic pollutants within the specific allowable limits established by the authority considering the mass proportion to five-year average flow, the permittee's treatment capabilities, the desire to maintain a pollutant capacity reserve and other factors that may be considered in the allocation of pollutant capacity for concentrations greater than normal wastewater.

(h) Oil and grease: 100 mg/l.

Suggested Maintenance Procedure

- A. Dip the accumulated grease out of the interceptor and deposit in a watertight container.

- B. Remove baffles if possible. Baffle size and structure are a function of the installed grease trap capacity. In some cases removal of the baffles is not practical.

- C. Scrape the sides, the lid, and the baffles with a putty knife to remove as much of the grease as possible, and deposit the grease into a watertight container.

- D. Remove solids from the bottom with a strainer or similar device.

- E. Replace the baffle (if necessary by previous removal) and the lid.

- F. Record the volume of grease removed on the maintenance log.

- G. Contact a hauler or recycler for grease pick-up.

The above information is provided for informational purposes ONLY! Proper maintenance and operational practices are the responsibility of the property owner and or business operator. Any and all questions should be directed to the trap manufacturer for specific instructions.